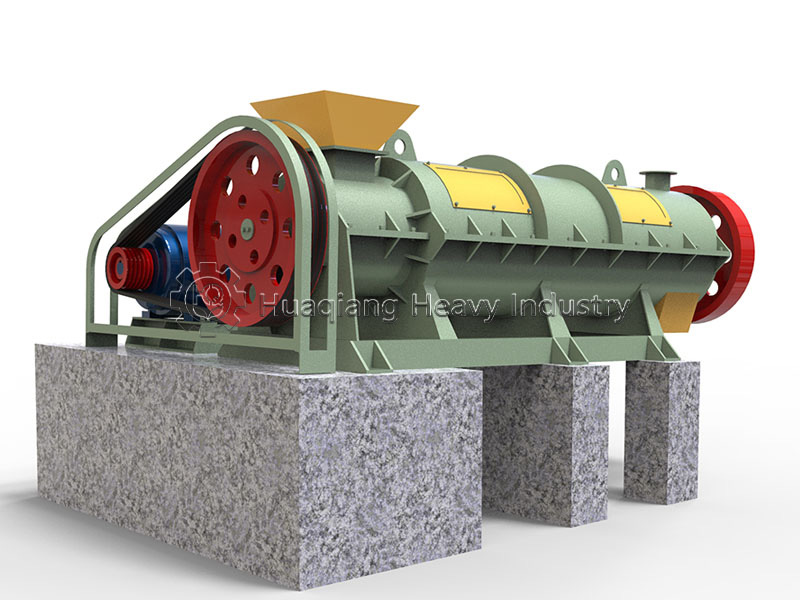

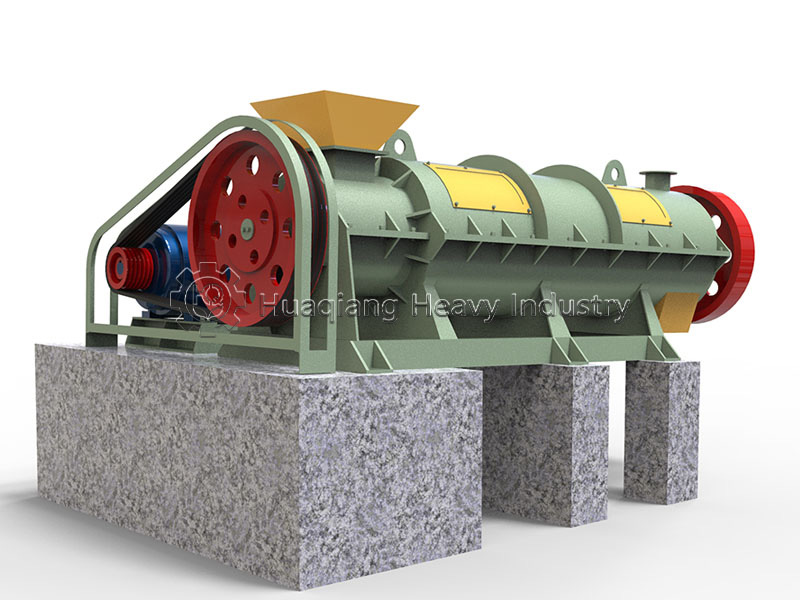

The new type organic fertilizer granulator utilizes high-speed rotating agitator teeth to produce granules. Its unique agitation and granulation method has distinguished it in the field of granule production. Its core operating principle is to feed the mixed material into the granulation drum, where the high-speed rotating agitator teeth vigorously stir, impact, and tumble the material. This causes the material to gradually agglomerate into granules due to friction, centrifugal force, and its own viscosity.

This granulation method does not require complex extrusion equipment and can meet the granulation needs of a variety of materials. It is particularly suitable for materials with high viscosity or containing certain fibers. Compared with other granulation equipment, the agitator granulator has a gentle granulation process, causes less damage to the material, and produces granules with good roundness and uniform size, making it suitable for small and medium-sized granulation production.

| Model | Capacity (t/h) |

Output Granules Size (mm) |

Motor Power (Kw) |

Outside Dimension (mm) |

| YSL-60 | 1-2 | 1-5 | 37 | 3700*1800*1050 |

| YSL-80 | 2-4 | 1-5 | 45 | 3700*2100*1300 |

| YSL-100 | 3-5 | 1-5 | 55 | 3750*2500*1500 |

| YSL-120 | 4-7 | 1-5 | 75 | 4900*2950*1900 |

| YSL-150 | 5-8 | 1-5 | 90 | 5000*3300*2150 |