Advantages of Non-drying NPK Fertilizer Production Process

2019/09/27

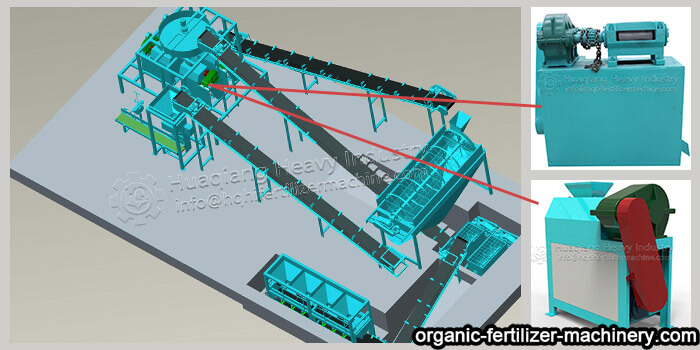

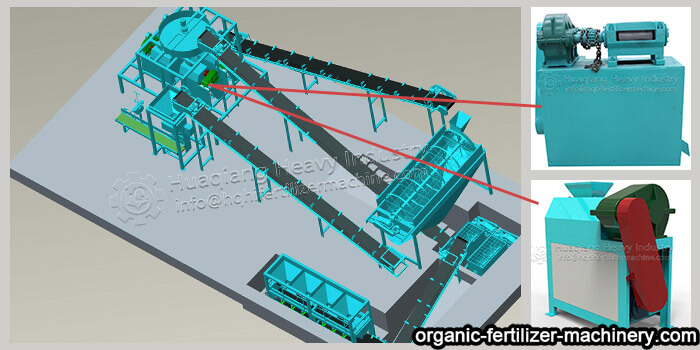

In recent years, according to NPK fertilizer production process, our factory has developed a new type of roller extrusion granulator for compound fertilizer production, which opens up a new way to improve the value of compound fertilizer products.

At present, the compound fertilizer production equipment in the market generally needs to be produced in a specific production environment, such as the production environment temperature, humidity and other external factors will affect the normal production of fertilizers. And there are many links in the production process, such as drying, and the production operation is more cumbersome. In view of this situation, we have developed the production process of NPK compound fertilizer without drying. This process is equipped with fertilizer roller extrusion granulator. In the processing process, the fertilizer granules can be produced at one time, and the fertilizer pelletizing rate is still more than 90%. In order to popularize the equipment of dry roller NPK fertilizer production process and meet the needs of different users, our factory has also made improvements in miniaturization and multi-function, and strengthened the practicability of the equipment. The roller granulator can granulate many kinds of materials. The volume of the equipment is smaller and occupies less land than other fertilizer granulator machine.

Fertilizer roller extrusion granulator has the characteristics of small investment, high efficiency, superior performance and convenient use. The compound fertilizer granulation is completed by using the dry roller extrusion production process, and the material is directly pressed into granules at room temperature. With this equipment, multi-component compound fertilizer based on ammonium carbonate, urea, ammonium chloride and ammonium phosphate has high strength and good slow-release performance. It achieves the effects of long-term, controlled-release and slow-release, and can increase the fertilizer efficiency by more than 20%. At the same time, the equipment also solves the problems of insufficient strength of organic fertilizer granules produced by fertilizer granulator machine (such as drum granulator and disc granulator). In addition, due to the use of dry powder roller NPK fertilizer production process, the material characteristics in production are not lost.