Organic fertilizer is not only an ideal base fertilizer in agricultural production, but also serves as topdressing, providing various nutrients for crops during their growth period. Organic fertilizer, commonly known as farm manure, refers to slow-release fertilizers that contain a large amount of biological substances, animal and plant residues, excreta, biological waste, and other substances. Organic fertilizer not only contains essential large and trace elements for plants, but also rich organic nutrients. Organic fertilizer is the favorite fertilizer for crops.

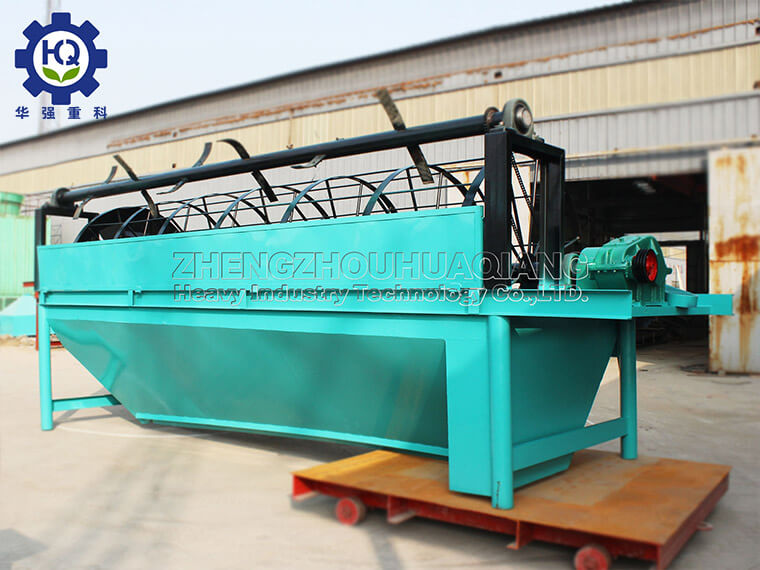

The pig manure organic fertilizer drum screening machine is a commonly used equipment in fertilizer production. It is mainly used for the separation of finished products and returned materials, and can also achieve product grading to ensure uniform classification of finished products. The machine adopts a combination type screen, which is easy to maintain and replace. Its structure is simple, operation is convenient, and operation is stable, making it an ideal equipment in compound fertilizer production.

The characteristics and advantages of the pig manure organic fertilizer drum screening machine:

1. High integrity: Except for the finished material stacking belt conveyor, all systems are integrated into a single overall framework, ensuring the integrity of the equipment while leaving appropriate maintenance and inspection space. Highly integrated, convenient and safe for storage or transportation at the construction site.

2. Work reliability: The screening system at the core of the drum screening machine adopts the mixing principle of a mixer. The raw materials are subjected to continuous spiral blades rolling, pushing, and mutual friction between materials in the mixing drum, with strong natural and high reliability.

3. The rolling screen cylinder is horizontally placed to ensure that the material flow is rolled more than four times between the spiral blades of the screen cylinder, causing the sand material to repeatedly roll and fully disperse and screen. Different from the phenomenon of incomplete screening and mixing caused by the mutual impact and squeezing of large and small materials or the vibration of large and small materials caused by inclined rolling screens or inclined vibrating screens.