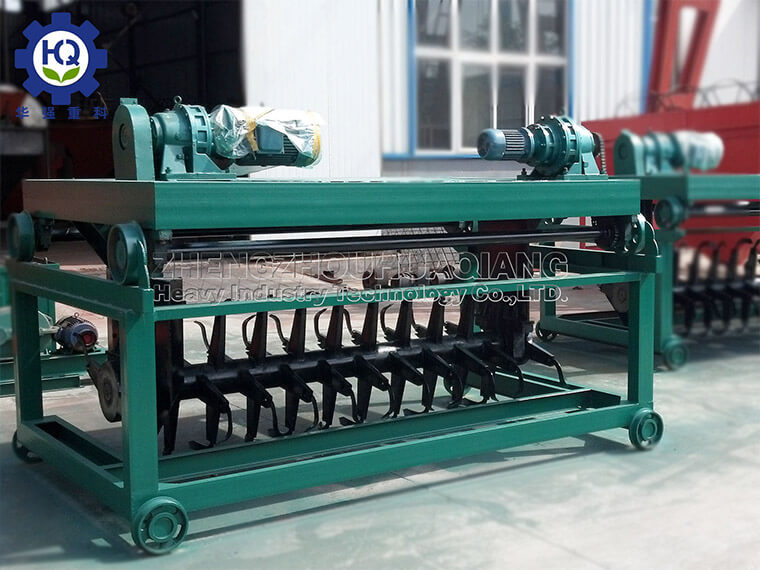

The equipment for fermenting organic fertilizer from sludge and cow manure is commonly referred to as a guide rail type tipping machine. It can be used for the fermentation and flipping of organic waste such as livestock and poultry manure, sludge waste, sugar factory filter mud, residue cake, and straw sawdust. It is widely used in the fermentation, ripening, and water removal operations of organic fertilizer plants, compound fertilizer plants, sludge waste plants, horticultural fields, and mushroom cultivation plants.

The slot type tipping machine can move from one fermentation tank to another through a transfer car, and multiple fermentation tanks can use slot type tipping machines. The slot type tipping machine can be used in ambient temperatures ranging from -20 ℃ to 50 ℃, and it also has strong adaptability to the characteristics of fermentation materials. According to the particularity of fermentation materials, the slot type tipping machine is made of corrosion-resistant materials,

The tank type fermentation tipping machine has a reasonable structure, high efficiency, low energy consumption, high degree of automation, convenient use, and low cost, making it a highly efficient model that is popular among users.

The structural characteristics of the organic fertilizer equipment for sludge cow manure fermentation: The organic fertilizer tank type fermentation tipping machine is divided into two units: a tipping unit and a tank changing unit. The tipping unit is mainly responsible for moving the tipping unit back and forth within the fermentation tank, while the tank changing unit is responsible for moving back and forth between the tipping unit and each fermentation tank. This machine can achieve multiple tanks for one machine.

The slot type stacker has the characteristics of good maneuverability and high output rate, which can improve labor productivity, save manpower, and achieve the goal of reducing production costs and improving product quality; It is a new type of product with low investment and high returns; It also has functions such as stirring and crushing, and is an essential key equipment for fertilizer making enterprises.