Fermentation process of chain plate flipper for pig manure organic fertilizer equipment

2024/02/23

Chain plate stacker is one of the tank fermentation stacker, which walks on the track above the fermentation tank during operation. This kind of composting machine is a kind of fermentation composting equipment commonly used by organic fertilizer manufacturers. It is very convenient to use, and the composting is complete. Moreover, it can be made into various models to cover a variety of fermentation output requirements. Therefore, this chain plate composting machine is very popular with users. Next, Zhengzhou Yicheng organic fertilizer equipment factory will briefly introduce the use method of this equipment, hoping to help you.

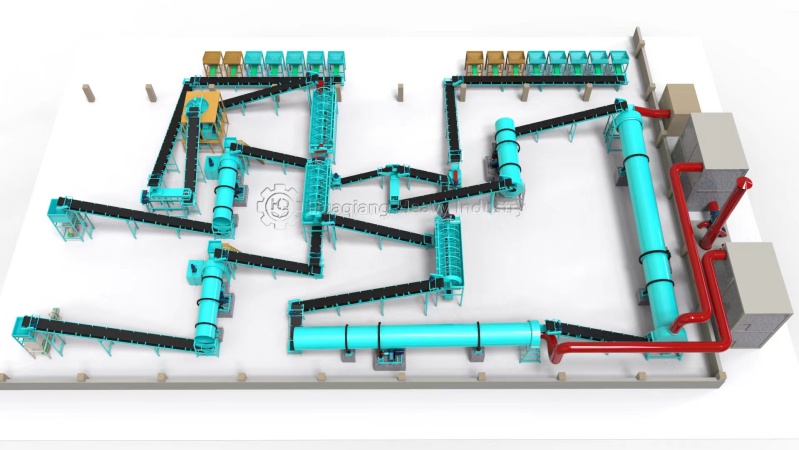

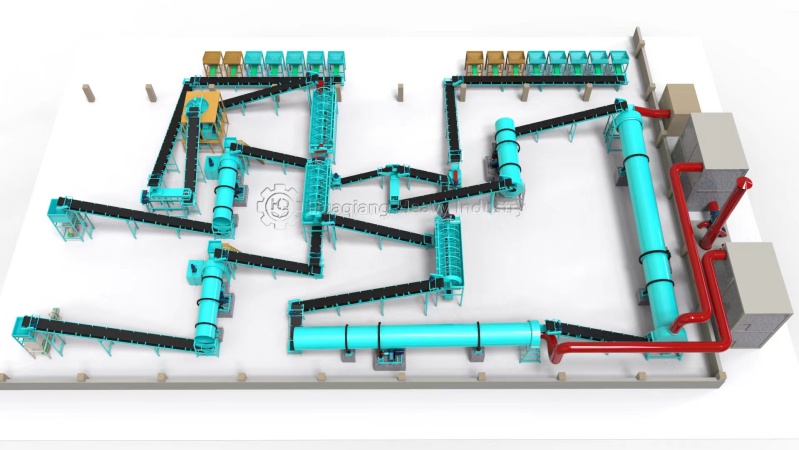

Chain compost turning machine in pig manure organic fertilizer equipment: It is suitable for multi-tank aerobic fermentation process for composting production. The high-speed rotating chain plate is used to toss, aerate and stir the compost materials in the fermentation tank with high efficiency and thorough turning, which can effectively shorten the fermentation cycle and improve the quality of compost. Structural features: The equipment can adapt to the multi-tank fermentation composting process with the matching tank changing and reversing mechanism. Under the conditions of equipment capacity, only the addition of fermentation tanks can expand the production scale, improve the use value of organic fertilizer equipment, and promote the smooth production of organic fertilizer production lines. With stepless automatic winch. The machine is designed for the pool type hair enzyme system, which is divided into three parts: main engine, track and transfer flat car. The tipping mechanism of the main engine is a unique multi-tooth chain plate structure, which is flipped up and down at a large Angle through the traction device. Under the action of the vertical and horizontal walking mechanism, the vertical lifting mechanism digs the fermentation material from the bottom of the pool to the horizontal conveying mechanism, and piles the enzyme material 8-10 meters into the pool, so that the fermentation material generates a certain displacement in the pool. The material is sent to the tipping machine layer by layer from top to bottom, and the material is piled in the fermentation tank layer by layer from bottom to top after discharge through the discharge port. The material in the tank has a continuous constant distance gradual backward movement, thus forming a continuous aerobic fermentation process, so as to complete the stacking work of the material.