Organic fertilizer and compound fertilizer are two kinds of common fertilizers in the market. Their processing technology is different, and the fertilizer effect is different. The organic fertilizer mainly uses the manure of artificial fermentation as the raw material, and the compound fertilizer is the granular fertilizer made of NPK fertilizer. To produce fertilizer, you should know the following common sense.

Organic fertilizer is made of fresh chicken and pig manure, which do not contain any chemical components. However, the digestion capacity of chicken and pig is poor, and only 25% of the nutrients can be consumed. The other 75% of the nutrients in the feed are discharged with the manure, so that the finished product contains nitrogen, phosphorus, potassium, organic matter, amino acid, egg white matter and other ingredients. The production equipment of chicken manure organic fertilizer not only creates economic benefits for the enterprise, but also makes contribution to the environmental protection project of human beings.

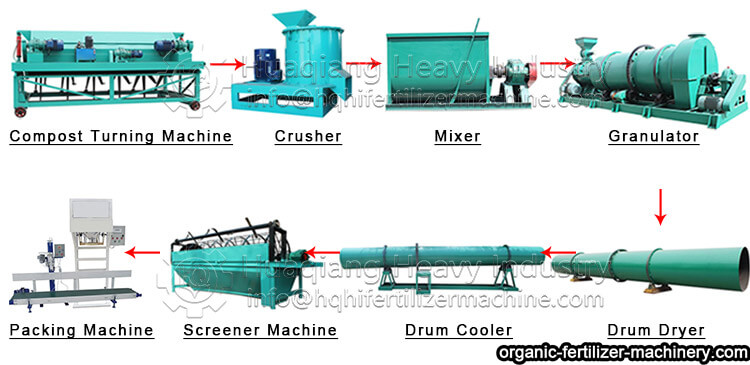

Drum screening machine, batching system, LP series chain crusher, mixer, drum screening machine, cage crusher, NPK fertilizer granulator, double roller granulator, drum granulator, high humidity material dryer, cooler, packaging machine.

Compared with the compound fertilizer machine, the organic fertilizer production equipment has more fermentation compost turning machine and semi wet material grinder.

Ferment compost turner machine

Trough-type turner is a kind of fermentation composting equipment that is widely used at present. It includes walking fermentation tank body, walking rail, power take-off device, turning and dumping part and turning tank device (also called transfer truck, which is mainly used for In the case of multi-slot use). The turning part adopts advanced roller drive, which can be lifted or not. Lifting type, the depth of turning can not exceed 1.3 meters. The bearing seat of the turning device is fixed on the turning frame, two main shafts are fixed on the bearing seat, each main shaft is welded with a number of turning shafts arranged at a certain distance and staggered at a certain angle, each turning pile Stacking plates are welded on the shaft. The stacking device is connected to the walking device through a pin.