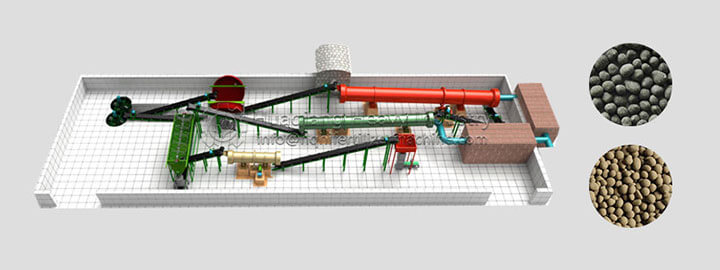

The organic fertilizer production line is a complete chain that converts agricultural waste into green fertilizer. The whole process is based on environmental protection concepts and scientific processes. The following is a detailed explanation of the core process.

Raw material pretreatment is the first checkpoint. Raw materials such as straw and livestock manure need to be crushed, mixed according to the appropriate carbon-nitrogen ratio, and fermentation agents added. High-moisture materials need to be adjusted with sawdust, and low-moisture materials need to be properly hydrated to create the best environment for microbial activity and allow subsequent fermentation to proceed smoothly.

The fermentation stage mainly adopts two methods: compost turning or strip fermentation. Trough fermentation is stirred daily by a turning machine to maintain a suitable pile temperature to kill insect eggs and pathogens. Strip fermentation requires regular manual turning of the pile, and after a period of time, the compost is dark brown and odorless, and the organic matter content can also be significantly improved.

The granulation process needs to select a suitable process according to the characteristics of the material. Dry granulation is suitable for composted dry powder, which is granulated by a double roller press granulator without the need for drying, and can well retain the effective ingredients in the material. Wet granulation is used for high-humidity materials. The materials are agglomerated into balls with the help of disc or rotary drum granulators, and then processed by drum fertilizer dryers to make the moisture reach the appropriate standard.

Subsequent processing includes cooling, screening and packaging. The drum fertilizer cooler reduces the temperature of the particles to room temperature to prevent high temperature from affecting the quality of the fertilizer. The drum screener machine separates unqualified particles and re-granulates them to ensure that the finished particles are uniform. Finally, the finished products are weighed and sealed by automatic packaging machines for easy storage and transportation.

The entire production line can be automatically controlled, with a wide range of production capacity. The organic fertilizer particles produced are uniform and the fertilizer effect is long-lasting. It plays an important role in promoting the development of ecological agriculture, which not only solves the problem of agricultural waste treatment, but also provides high-quality fertilizer for crop growth.