Manure, commonly known as farmyard manure, consists of various animal and plant residues or metabolites, such as human and animal dung, straw, animal residues, slaughterhouse waste, etc. Carbon containing materials mainly derived from plants and/or animals, applied to the soil to provide plant nutrition as their main function. It is processed from Biogenic substance, animal and plant wastes, and plant residues, eliminating toxic and harmful substances, and rich in beneficial substances, including a variety of organic acids, peptides, and rich nutrients including nitrogen, phosphorus, and potassium. It can not only provide comprehensive nutrition for crops, but also has a long fertilizer effect. It can increase and renew Soil organic matter, promote microbial reproduction, improve the physical and chemical properties and biological activity of soil, and is the main nutrient for green food production.

With the continuous strictness and strengthening of environmental protection in various regions, many areas have blocked the external discharge ports of breeding farms and are not allowed to discharge from them. Farming continues, and the septic tanks are becoming increasingly full. Even increasing the number of septic tanks is still a drop in the bucket.

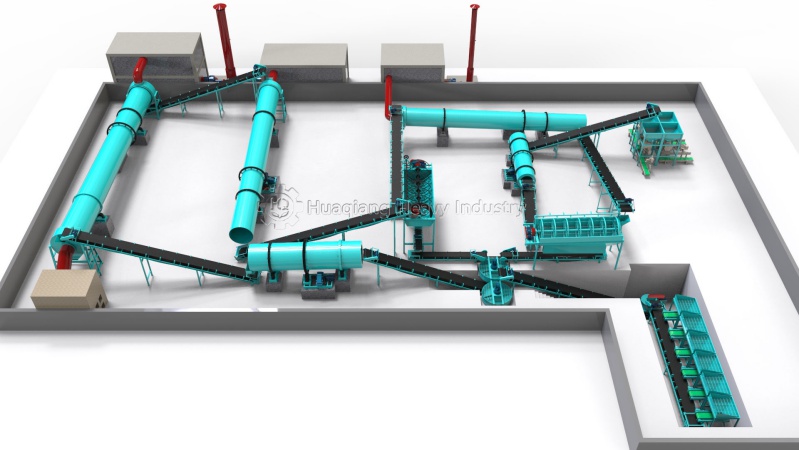

The technological process of Organic fertilizer production line to process farm manure into fertilizer:

1、 Raw material and ingredient ratio

Mixing manure with crop straw depends on the moisture content of sheep manure. According to the fermentation process, the moisture content is required to be within 45%, which means that when the material is kneaded into a ball, water can be seen, but water will not drip down. If the ball is loosened, it will disperse. Then, add corn flour and determine the required bacterial strains. The reason for corn flour is to increase its sugar content for promoting rapid fermentation of bacterial strains.

2、 Material mixing

Add the configured materials to the material mixer for mixing, ensuring that the mixture is uniform, transparent, and does not leave any lumps.

3、 Material fermentation

Then, the mixed materials are stacked in a fermentation tank or tank with a width of 2-6 meters and a height of 1.0-1.5 meters. Every other day, the flipper and stacker flip and flip repeatedly. Usually, in a fermentation tank, the temperature will increase after 2 days of stacking, there will be no odor after 2 days, it will become fluffy and loose after 3 days, compost will emit a fragrance after 2 days, and it can become fertilizer after 15 days.

4、 Fermentation process

1. In the fermentation tank for 2 days, the temperature will rise to 60 ℃ -80 ℃, which will sterilize and eliminate pests.

2. On the the fourth day in the fermentation tank, eliminate the odor; Then on the seventh day, the material in the tank will become loose, dry, and covered with white hyphae.

3. On the ninth day of fermentation in the tank, Jiu will emit a fragrance that is basically similar to the aroma of koji.

4. On the tenth day of fermentation in the tank, the material will be fully fermented and matured.

5. It represents the end of the fermentation stage, and materials can be removed to the next process using a forklift or other means.

5、 Granulation and drying process

The materials moved by the forklift to the crushing process are crushed by a semi wet and high wet material grinder, and then mixed by a mixing mixer. They are transported by a conveyor to the Organic fertilizer granulator for granulation. The particles made are sent by a belt conveyor to a dryer for drying, and then cooled by a cooler, and then sent by a conveyor to a screening machine for screening

6、 Screening and packaging

More than 95% of the particles that meet the requirements will enter the next process, while about 5% of the particles will be transported to the Organic fertilizer crusher for further crushing and granulation. The particles that meet the standards will enter the coating machine for coating, which can maintain nutrients. After coating, the automatic packaging machine will be used for packaging. In this way, the fecal Manure is processed and packaged, and can be put into storage for sale.