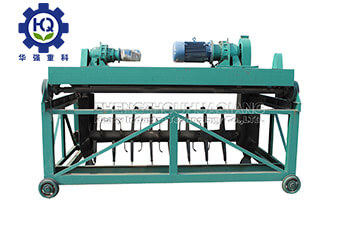

The trough type large-scale organic fertilizer dumper operates along the track of the fermentation tank. Because of its high compliance and large displacement dumping operation, it is conducive to accelerating the fermentation and decomposition of materials in the fermentation tank, lowering the water content and composting quality. This series has many specifications and advantages such as the width and length of various fermentation tanks. The organic manure turnover machine is widely used for deep tank aerobic composting of livestock manure, sludge, garbage and other organic solid destruction. The work is reasonable. The chain plate organic manure fermentation chain plate organic manure fermentation chain plate turnover machine in the intelligent automatic control of the turnover of fermentation materials, the multi toothed plate structure conveyor forms an included angle of 45 degrees with the pool bottom materials under the traction of the driving device, The scraper on the chain plate circulates to pick up the fermentation materials continuously and gradually, transport them to the point along the bottom of the tank, and then throw them down, so that the materials are piled up again and displaced. This results in a continuous aerobic fermentation. The decision of one machine with multiple pools realizes the set-up difference of limited production.