Bio-organic fertilizer uses organic waste such as livestock and poultry manure, crop straw, etc. as raw materials. After being processed through a specific process, it becomes a fertilizer rich in organic matter and beneficial microorganisms. Therefore, the bio-organic fertilizer production line needs to take into account both maturity and biological activity.

Raw material pretreatment is the primary step. The collected manure is air-dried to an appropriate moisture content, and the straw is crushed into small pieces. The mixture is then mixed to adjust the carbon-nitrogen ratio to the appropriate range. If the raw material is highly acidic, a small amount of quicklime can be added to neutralize it. Impurities such as rocks and plastic are also removed to prevent interference with subsequent fermentation.

The core process is high-temperature aerobic fermentation. The mixture is piled into long windrows, inoculated with a complex inoculant such as Bacillus subtilis and yeast, and regularly turned by a turner to ensure adequate oxygenation. During the fermentation process, the optimal temperature must be maintained to kill insect eggs and pathogens while promoting microbial activity. After a period of time, the material turns dark brown and becomes odorless, indicating that composting is complete.

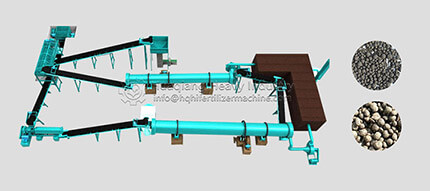

The matured material enters the advanced processing stage. The pellets are first crushed to a desired fineness in a pulverizer. Functional microbial agents such as nitrogen-fixing and phosphate-solubilizing bacteria are then added and mixed thoroughly to ensure the required viable bacterial count. They are then granulated in a new type organic fertilizer granulator. During this process, the material must be kept at an appropriate moisture level to ensure stable pellet formation.

Next, the pellets undergo drying, cooling, screening, and coating. They are dried in a low-temperature dryer to prevent the heat from killing beneficial bacteria. Once the moisture content is reduced to an appropriate level, they enter a cooler to cool down to near room temperature. This prevents clumping caused by high temperatures in subsequent steps and helps maintain microbial activity. The cooled pellets are screened by a vibrating screen. Qualified pellets enter a coating machine, where they are sprayed with an appropriate amount of coating agent to form a thin film. This reduces moisture absorption and clumping during storage and transportation, slows nutrient release, and improves nutrient utilization. Fine particles are then screened and returned to the granulation process.

Finally, packaging occurs. The coated products are sampled and tested to confirm that the organic matter content and viable bacterial count meet the required standards. They are then weighed, packaged, and stored. This entire process not only recycles waste but also provides sustainable nutrients for the soil.