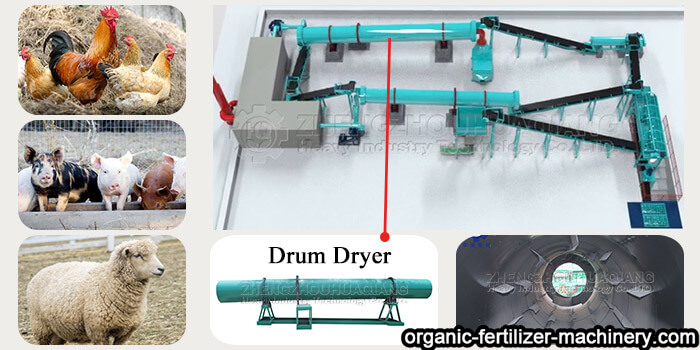

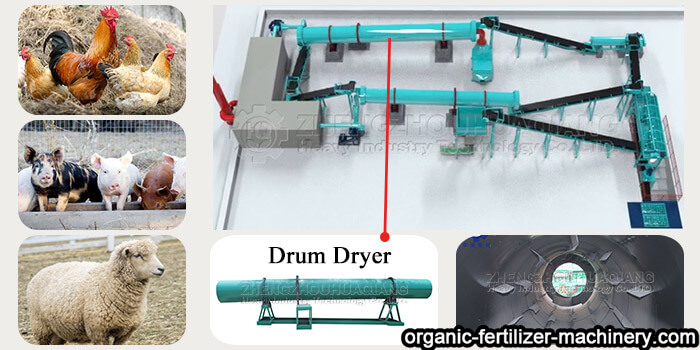

Dryer Equipment of Organic Fertilizer Production Line for Manure Treatment

2019/05/10

Livestock and poultry excrement pollution is the main factor restricting the development of animal husbandry. If excrement can not be treated in time, it will have a great impact on the environment and the surrounding areas. Organic fertilizer production line can make organic fertilizer with high value by treating wastes such as feces in large quantities. Organic fertilizer production line solves the problem of livestock and poultry excrement treatment and purifies the environmental pollution of livestock and poultry.

Rotary drum dryer of Zhengzhou Huaqiang Heavy Industry brand can solve all kinds of pig manure, chicken manure and other livestock manure waste. This drying equipment creates conditions for the resource utilization of pig manure, chicken manure, cow manure and other wastes. The drum dryer used in organic fertilizer production line has a unique sheeting design, which can dry high-humidity materials at one time to the required moisture content.

Rotary drum dryer has the characteristics of low energy consumption and high efficiency. It is specially used in organic fertilizer production line and high moisture organic waste treatment. This dryer adopts the downstream drying process in the organic fertilizer production line. The hot gas enters the drum to exchange heat with the material, and the material can be dried. The wet granules produced by the granulator are transported into the dryer. The material is copied to a certain height by the sheet on the rotary drum and then falls down. During the falling process, the granules are fully in contact with the hot air, and the material dries rapidly. The dried granules are directly conveyed to the durm cooler in the organic fertilizer production line for cooling. The dust collector collects the exhaust gas generated during drying and discharges the exhaust gas after treatment to reduce pollution.