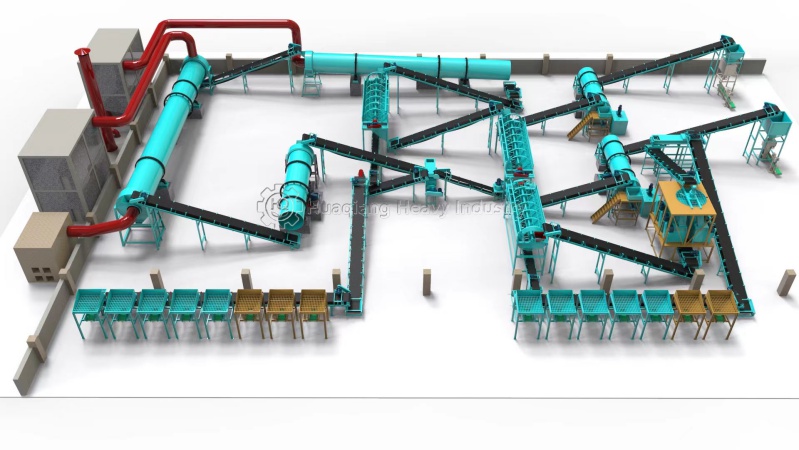

The medium-sized NPK fertilizer production line has higher requirements for yield and product quality, and its equipment configuration is more complete.

In the raw material processing stage, a large hammer crusher is equipped to efficiently crush raw materials of various hardness, with a large processing capacity and uniform crushing particle size. At the same time, a dedicated raw material elevator is set up to quickly transport the crushed raw materials to the storage bin.

The measuring and batching process adopts high-precision weight loss measuring scales, which can monitor the flow rate of raw materials in real time, achieve continuous and accurate batching, and ensure the stability of fertilizer nutrient ratios.

The mixing equipment uses a dual axis blade mixer, which has high mixing efficiency and good mixing uniformity. It can quickly and fully fuse multiple raw materials, and even trace additives can be evenly distributed in fertilizers.

The granulation equipment adopts a rotary drum granulator, which produces high-strength and regularly shaped granular fertilizers through the rolling, collision, and bonding of materials in the rotary drum. The rotary drum granulator has high production efficiency and is suitable for medium scale production.

The drying process uses a drum dryer to quickly dry fertilizers using high-temperature hot air, which has a good drying effect and can effectively kill harmful bacteria. The dryer is equipped with an advanced temperature control system to ensure a stable drying process.

The cooling equipment adopts a counterflow cooler, which can quickly cool the fertilizer, improve the hardness and glossiness of the particles, and reduce the rate of particle damage.

The screening equipment uses a three-layer vibrating screen, which can accurately screen fertilizer particles with different particle sizes and separate unqualified particles for secondary treatment.

In order to improve the appearance quality and anti caking performance of fertilizers, a coating machine is also installed to coat fertilizer particles.

Finally, the packaging equipment adopts a fully automatic packaging production line, which has functions such as automatic measurement, sealing, labeling, etc. The packaging speed is fast and the accuracy is high, which can meet the packaging needs of medium-sized production.

The equipment configuration of the medium-sized NPK fertilizer production line takes into account production efficiency, product quality, and automation level, and can produce high-quality NPK fertilizers to meet the needs of a wider market.