The roller granulator uses pressure to agglomerate solid materials together, and then squeezes the materials by two counter-rotating rollers, which are driven by an eccentric sleeve or a hydraulic system. When the solid material is squeezed, the air between the powder particles is first removed to rearrange the particles to eliminate the gaps between the materials.

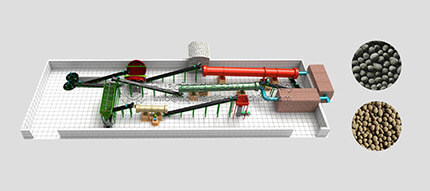

The roller granulator has the advantages of advanced technology, reasonable design, compact structure, new and practical, low energy consumption. It forms a small production line with corresponding equipment, and can form a certain capacity of continuous production.

Roller granulator organic fertilizer manufacturing process uses a variety of fertilizer formulations, no need to dry, room temperature production, product rolling forming, so that the product quality meets the technical index requirements of compound fertilizer. Roller granulator is suitable for the production of high, medium and low concentration special compound fertilizers for various crops. It is a new product for energy saving and consumption reduction in NPK fertilizer industry.

The shape and size of the ball and socket on the roll skin of the roller extrusion granulator can be selected according to user needs, and there are larger options. The ball press shapes include pillow shape, semi-circular pellet shape, rod shape, tablet pill shape, and walnut shape. , Fan ball and square shape. At present, they are all oblate spheroids.