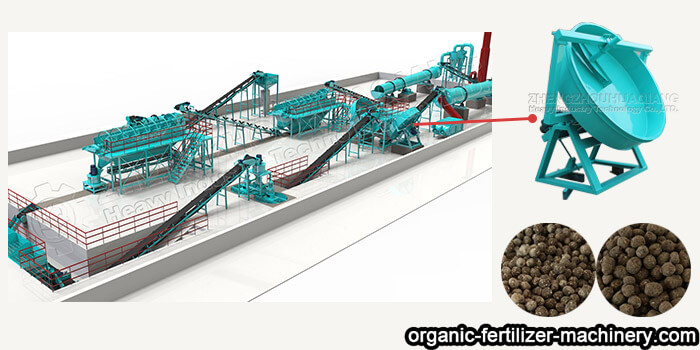

The equipment and technology of small and medium-sized organic fertilizer production lines are basically divided into two types: powder and granules. As a user, not only must have a clear understanding of the production process of the entire organic fertilizer manufacturing process, but also must be aware of the components of the equipment and accessories. Whether we choose fermentation equipment, granulation equipment or conveyors, we need to make reasonable choices based on technology, site, and capacity.

Disc granulation processing

In the production of organic fertilizer, the choice of granulation method is very important. Among them, the cow manure organic fertilizer disc granulator is intuitive to operate, simple to control, less vulnerable to equipment, small maintenance, but small processing capacity of a single machine.

In the organic fertilizer production line, two disc granulators can also be used. A discharge port is opened at the original disc granulator outlet, and the discharge port is connected to a discharge trough. The end of the discharge trough is equipped with another disk manufacturing granulator. After the batched material is formed by the original disc granulation machine, it enters through the discharging port and the discharging trough, and then the disc granulator is installed for secondary disc finishing, which increases the roundness of particles and increases the content of medium-sized particles. , Improve the granulation rate, the granulation rate is as high as 95.0%, greatly reducing the re-production ratio.