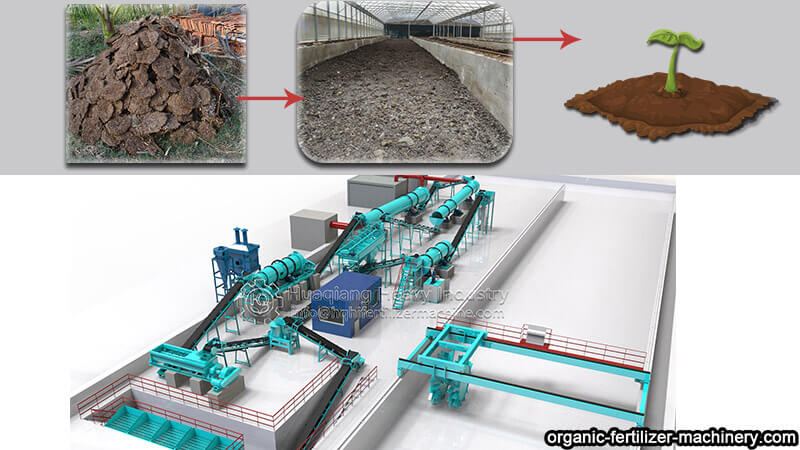

In the breeding yard, the compost turning machine of livestock and poultry manure is collecting the row and ploughing of livestock and poultry waste. After the fermentation process of high temperature aerobic composting, livestock and poultry waste becomes microbial organic fertilizer, creating value.

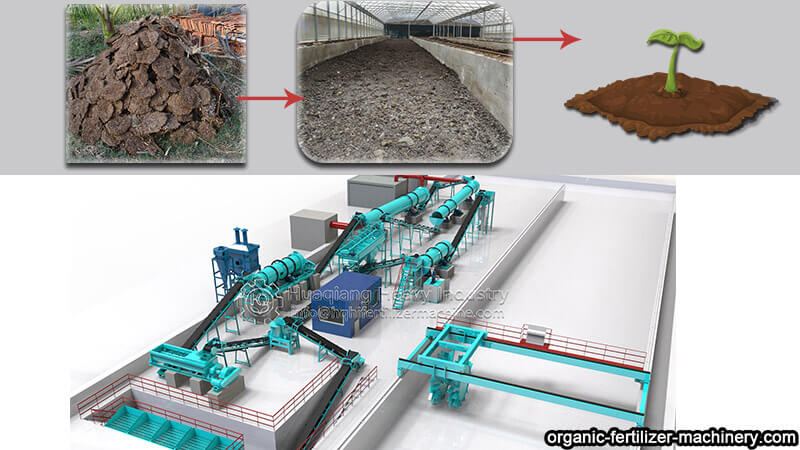

If a large amount of chicken manure is not treated without harmlessness in time, it will affect the surrounding environment. To eliminate the pollution of livestock waste, cattle farm and poultry farm purchase aerobic fermentation turner of livestock and poultry manure, invest in organic fertilizer production equipment, and convert livestock and poultry waste and straw waste into organic biological fertilizer. By adopting advanced aerobic composting technology, 3000 tons of organic manure can be produced every year.

In livestock and poultry breeding, the feces produced have been one of the main agricultural pollution. The organic fertilizer production equipment can reprocess the organic wastes such as livestock and poultry manure, and make use of the activity of microorganisms to decompose and mature the organic matter in the waste. The compost is made into granular fertilizer by the fertilizer granulator. The price of fertilizer per ton is much higher than that of general fertilizer. If applied to greenhouse vegetable planting, this kind of organic fertilizer product can be an important product to improve soil and increase organic matter, and realize recycling of organic waste.

The aerobic composting fermentation technology used in the production of organic fertilizer is a process of stabilizing the organic matter in the feces through the aerobic turning machinery of livestock and poultry waste under aerobic conditions. After the moisture content is appropriate, add the bacteria to it, and the aerobic compost has a stack and a static aerated compost form. The decomposed compost is processed into solid particles with drum granulator or other granulation equipment to obtain high-value fertilizer products.