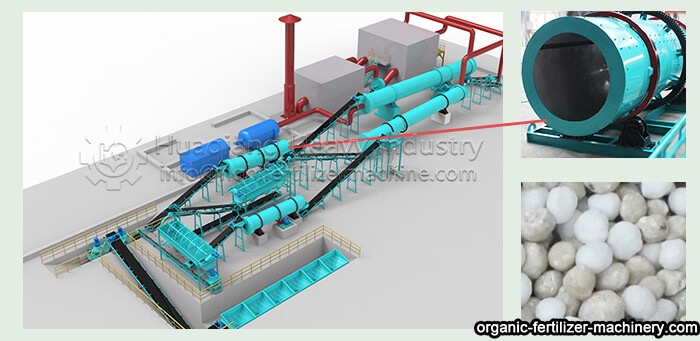

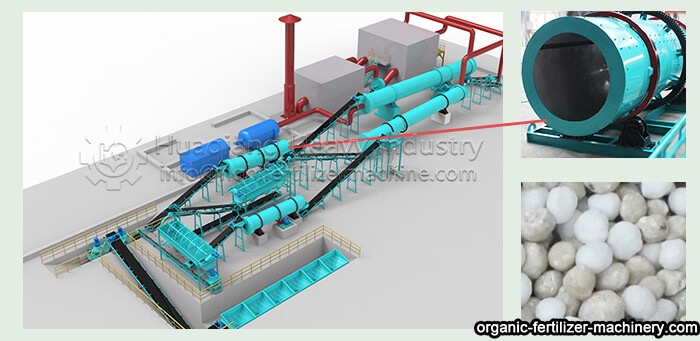

There are different kinds of granulating equipment for different raw materials in organic fertilizer manufacturing process. Many fertilizer investors do not know which granulator equipment they need to use to produce fertilizer. Here we will explain to you the granulation equipment in a very widely used pelletizer - rotary drum granulator.

Drum granulator is a kind of granulating equipment widely used in the production of compound fertilizer, organic fertilizer, biological fertilizer, controlled-release fertilizer and other fertilizers. It is suitable for cold and hot granulation in temperature, and suitable for large-scale production of various NPK fertilizers with high, medium and low concentrations in terms of concentration.

Main working mode

Rotary drum granulator uses wet granulation, and the disc granulator is also the granulation method. Through a certain amount of water or steam, the drum pelletizer can make the crushed materials fully chemical reaction after humidity adjustment in the cylinder. Under certain liquid phase conditions, with the help of the rotary motion of the cylinder, the material particles will produce extrusion pressure and agglomerate into balls.

Principle of granulation

Rotary drum granulator manufactured by our factory uses a special rubber sheet lining or acid-resistant stainless steel lining, which has high ball strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, operation and maintenance convenience and other features.

The drum pelleting machine is filled with steam, gas ammonia or phosphoric acid or nitrogen solution, phosphorous ammonia slurry, heavy calcium slurry, and the compound fertilizer granulation process of chemical reaction and heating is completed in the drum; or a small amount is added The process of cold granulation of compound fertilizer with moisture. The material to be granulated is passed through the rotating movement of the cylinder, and the cylinder is not material to produce rolling rotation. Under a certain humidity and temperature, it will be agglomerated into balls to complete the ball making process.