With the development of agricultural economy and technology, more and more attention has been paid to sustainable development. The good benefits of organic fertilizer have been welcomed more and more. The market also has good feedback on the production equipment of organic fertilizer. Organic fertilizer equipment solves the problem of pollution caused by part of waste. Organic fertilizer produced by organic fertilizer equipment meets the needs of agriculture and is of great significance to agriculture. Here's how to buy organic fertilizer equipment.

Determine the capacity of organic fertilizer production line. For example, how many tons are produced in an hour and how many tons are produced annually, the specifications of organic fertilizer production equipment can be determined according to the output that you want to produce.

Determine the process flow and equipment of organic fertilizer production line. Fermentation, crush and granulation are indispensable processes in organic fertilizer production. Semi-wet material grinder, drying and cooling are generally selected in the crush stage of organic fertilizer production. So after choosing the output of the equipment, the turner is selected according to the size of the output in the fermentation stage. Groove turning machine and windrow turning machine are both equipment in fermentation. Groove turning machine is limited by fermentation tank, so it is necessary to build fermentation tank. However, the processing capacity of windrow turning machine is often smaller than that of groove turning machine. Groove turning machine and process can achieve rapid fermentation, at this time customers can choose the most appropriate according to their own production and fermentation cycle requirements.

Determine the granulator and particle shape. Generally used organic fertilizer granulation equipment are: disc granulator, drum granulator, new type organic fertilizer granulator, roller press granulator, flat die granulator, ring die granulator. The selection of granulator should be decided according to the preference of local fertilizer market. The particle shape is different, the production process of organic fertilizer is also different, and the allocation of organic fertilizer equipment is also different.

Determine the allocation level of organic fertilizer equipment. The level of equipment configuration is different, the ability of stable operation of equipment is also different, labor costs, maintenance costs, service life is different. There are more auxiliary equipments with high configuration, such as automatic batching system, automatic packaging machine, feeding device, cyclone dust collector, etc.

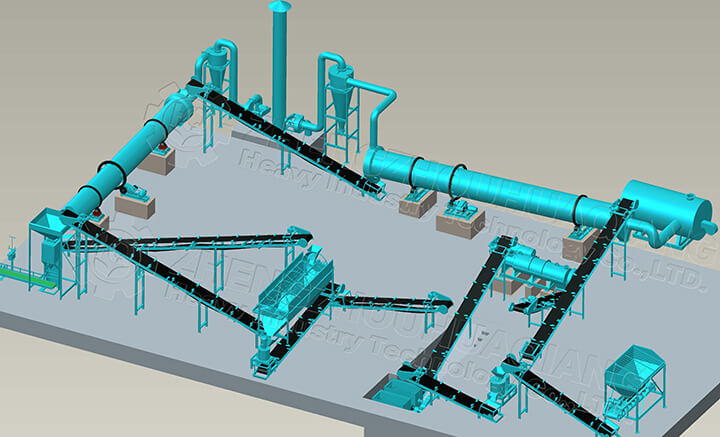

Standard configuration: dewatering machine, automatic batching system, loader feeding hopper, compost turning machine, crusher, mixer, granulator, dryer, cooler, screener, cyclone dust collector, coating machine, packing machine.

Simplified configuration: crusher, mixer, granulator, screening machine, packaging machine.

Specific equipment can be added according to own situation and investment.

Choose qualified organic fertilizer suppliers to provide after-sales service. To purchase qualified organic fertilizer equipment, it is important to check whether the supplier has relevant certificates, whether the production equipment is standardized, what kind of materials the equipment is used, whether safety protection is considered in equipment design, and after-sales service are also important factors.

Zhengzhou Huaqiang Heavy Industry Technology Co.Ltd. is mainly engaged in fertilizer production equipment, organic fertilizer production line, organic fertilizer granulator, compound fertilizer production and other fertilizer equipment. We offer comprehensive technical and business consulting services, proposing the most suitable scheme and equipment for our clients. Designing targeted products according to the special requirements of clients. Providing live motor commissioning video to examine the quality. On the after-sales service, we dispatch engineer to the site to guide installation, debugging and training operators. Installation and operation workers are offered if you need.