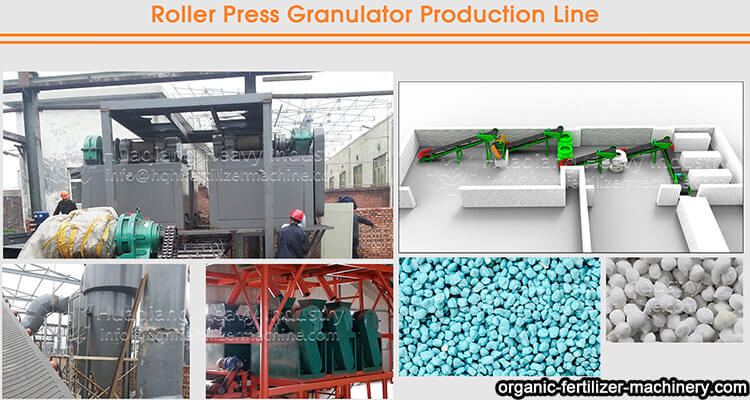

Double roller granulator is a new special equipment in granulation equipment. It uses dry granulation to make granules. As the key machine of fertilizer granulation, multifunctional double roller granulator plays an important role in organic fertilizer manufacturing process. We can use it to produce high, medium and low concentration targeted compound fertilizer.

If the user wants to build a small-scale fertilizer production line, the double roller extrusion granulator is a good choice. In addition, users can be equipped with multiple double roller granulator to form a fertilizer production line according to the production line and realization needs.

The fertilizer plant can produce a variety of different types of compound fertilizer through extrusion granulator, including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.; especially, it can be used to granulate rare earth, potassium and ammonium carbonate compound fertilizers.

Powders can contaminate the environment and are difficult to transport and store. By using this kind of roller press granulator, the powder is granulated into particles, which is more convenient for transportation and storage. More importantly, it uses dry granulation method, in the granulation process does not need to add any adhesive.