The organic fertilizer manufacturing process can realize the environmental protection cycle of agriculture. The organic fertilizer produced by the organic fertilizer equipment can turn the polluted waste into treasure. The expansion of the organic fertilizer production line and the utilization of chemical fertilizer can improve or reduce the amount of chemical fertilizer and increase the amount of organic fertilizer. Organic fertilizer manufacturing process is the real realization of agricultural material reuse, which can make the organic agriculture develop continuously.

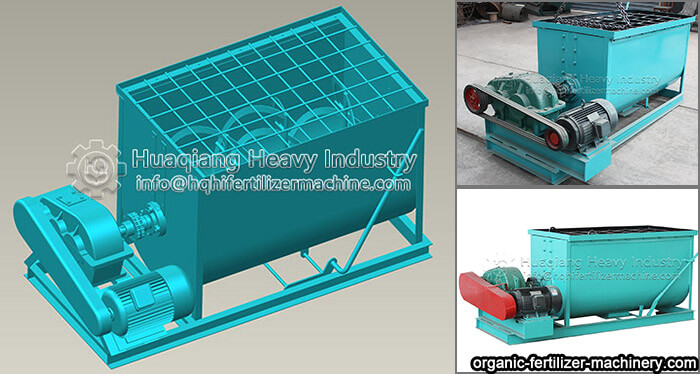

Operation of fertilizer mixer equipment

Turn on the power supply, start the motor of the mixer, drive the mixing parts to work through the sprocket deceleration drive, put all kinds of raw materials into the organic fertilizer mixer through the loader or manually according to the formula set by the electronic instrument, and mix, turn over, shear and knead all kinds of materials in the mixer through the cooling system, so as to fully mix all kinds of raw materials and strains. Finally, the discharging motor drives the switch of the discharging door to realize the discharging operation.

The mixing machine is set to mix the materials to be granulated evenly to meet the production process of NPK fertilizer granulator and facilitate processing. In addition, organic fertilizer equipment also includes start-up system, dust removal system and quantitative packaging system.