Soil is the main natural resource of agricultural production. Soil ecosystem composed of soil and its environmental conditions determines the sustainable development of agriculture. Organic fertilizer is the main fertilizer to improve soil. Organic fertilizer can not only improve crop quality and yield, but also improve soil fertility and reduce the use of chemical fertilizers. Organic fertilizer accounts for more and more proportion in agriculture.

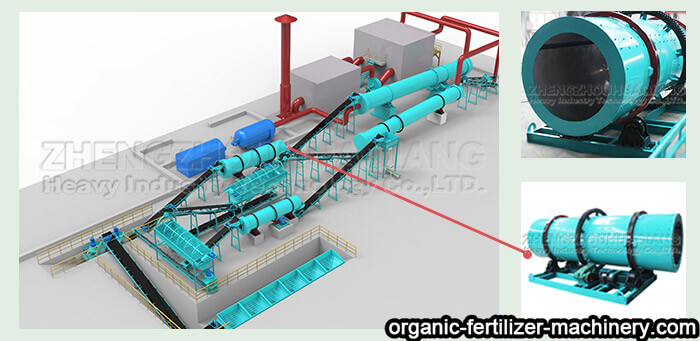

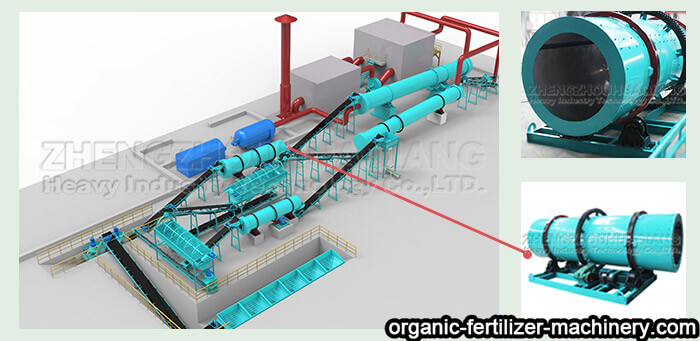

Rotary drum granulator is an agricultural equipment for producing organic fertilizer, which is widely used in the production of organic fertilizer and compound fertilizer.

The structure of drum granulator includes cylinder body, transmission device, front supporting wheel device and rear supporting wheel device. One end of the cylinder body is provided with a steam pipe, and the other end is provided with a feeding box. The cylinder body of the drum granulator is equipped with big gears, front wheel belt and rear wheel belt. The cylinder body is supported by front wheel belt and rear wheel belt on the front wheel bracket and rear wheel bracket device. The outer wall of the cylinder is equipped with big gears, and the transmission device drives the cylinder body to rotate through big gears.

Rotary drum granulator and other equipment in organic fertilizer production line can make organic fertilizer products by granulating, drying and cooling raw materials. Rotary drum granulation organic fertilizer production line only needs simple equipment processing to achieve the whole fertilizer process, improve product quality and improve crop production.

Raw material for rotary drum granulation organic fertilizer production line

3.Livestock manure: chicken manure, cattle, sheep, horse manure and rabbit manure, etc.

4.Agricultural waste: straw, mushroom residue, biogas residue, etc.

3. Industrial waste: distiller's grains, vinegar grains, cassava residues, sugar residue, furfural residue, etc.

4. Municipal sludge, biogas slurry and biogas residue.