Coated urea is a kind of modified urea. So why should urea be coated in the process of compound fertilizer production line? There are two reasons:

1. Urea is the nitrogen fertilizer variety with the highest nitrogen content (N≥46%). In recent years, the actual effect of fertilization has shown that urea is a fertilizer with low utilization rate. Due to the large total amount and the low utilization rate, the nitrogen loss caused by urea and the negative impact on the atmosphere and water environment are also greater.

2. The reason for the low agricultural utilization rate of urea is determined by the weakness of its agrochemical nature. The agrochemical properties of urea after entering the soil are similar to that of ammonium bicarbonate. It cannot be absorbed and stored by the soil before it is ammonified. The ammonification process is accompanied by the alkalization of the soil in the micro-region, which leads to the increase of ammonia (NH3) volatilization. The nitrogen content of urea is higher than that of ammonium bicarbonate, so in fact the total volatile content exceeds that of ammonium bicarbonate.

Material composition and processing technology of urea coating solutionThe coating solution is a jelly composed of organic and inorganic substances. In addition to organic substances such as humic acid, a little salt form of potassium (K), magnesium (Mg), manganese (Mn), and zinc (Zn) are added. , Iron (Fe), boron (B) and other nutrients. The coating solution is yellow-green, with a specific gravity of 1.17~1.18, and a pH between 3~4.

Urea coating process is to use the coating solution and urea particle surface has a certain affinity, a small amount of solution evenly sprayed on the urea surface, and a small amount of penetration into the urea particles, the amount of coating solution used per ton of urea is only 6-10 kg. With the help of heat drying and curing of urea, the coating solution can form a very thin film on the surface of urea particles after dry solid oxidation, which can be processed at one time.

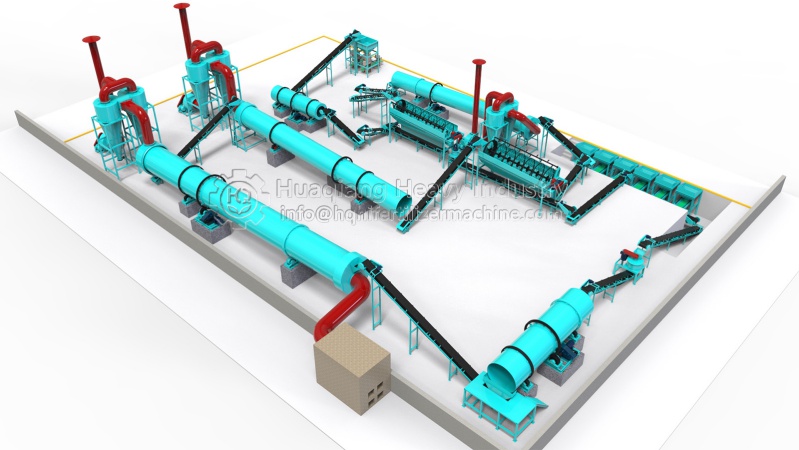

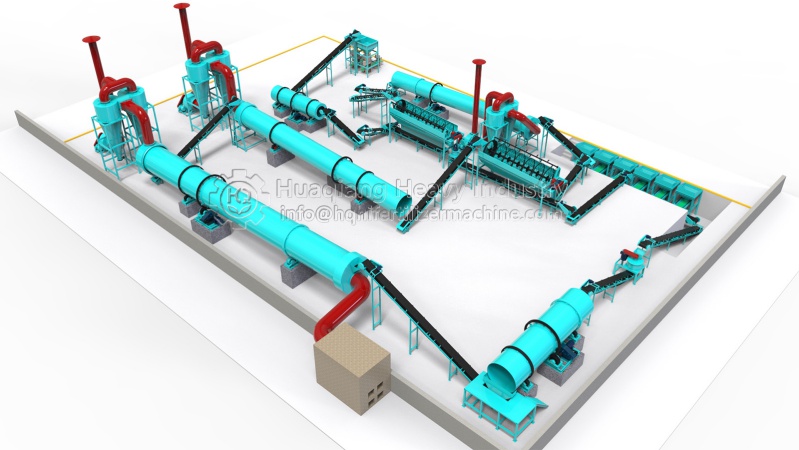

We not only provide equipment related to urea coating production process, but also fertilizer granulation machine, NPK fertilizer granulator, extrusion granulator, rotary granulator, flat die pellet mill, organic fertilizer granulator, disc granulator, etc.