The roller extrusion granulator has a wide range of raw materials for the production of compound fertilizer. The organic fertilizer double roller granulator has been successfully used for extrusion and granulation of more than 20 materials: urea, ammonium chloride in nitrogen fertilizer, etc. Phosphate fertilizers include ammonium phosphate, general calcium, heavy calcium, phosphate rock powder, etc., potash fertilizer, potassium sulfate, etc., and can add trace elements such as boron, iron, copper, zinc, and manganese.

In addition, the extrusion granulation fertilizer manufacturing process can flexibly change the product formula in a very short time, and a set of device can produce more than 30 formula products.

The particle size range of raw material matched with double roller granulator is large

Extrusion granulation has no special requirements on the particle size of raw materials. 1-4mm granular materials and fine powder materials can be used in compound fertilizer extrusion granulators, organic fertilizer extrusion granulators and unqualified powder materials and powders. Shaped products are better to use, and the use of powdered materials can reduce costs.

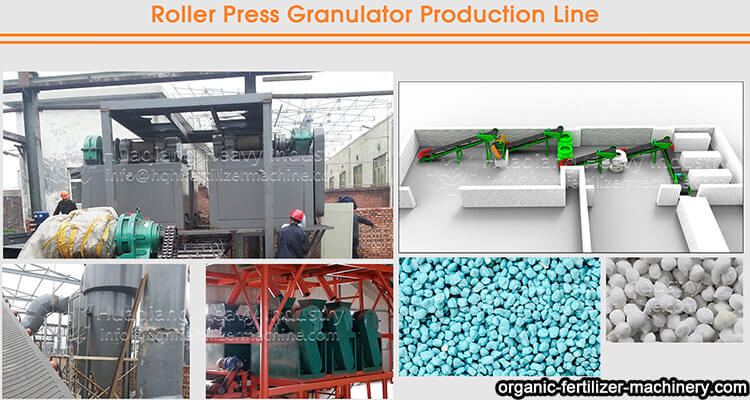

Organic fertilizer roller granulator is a kind of organic fertilizer granulation equipment that continues to be renewed with the development of agriculture, the improvement of technology and the diversity of demand. This kind of organic fertilizer manufacturing process can realize the selection of organic materials. It is an energy-saving and environmental protection equipment production line for biological organic fertilizer, without drying fertilizer production line.