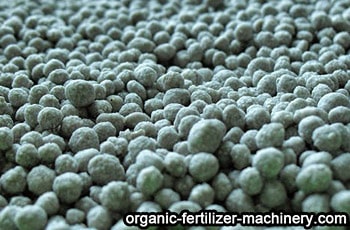

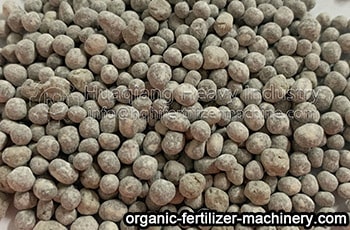

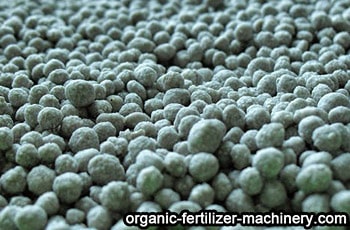

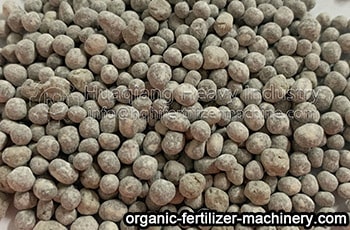

Fertilizer granulation is the key processing technology of organic fertilizer production line. The quality of granulation directly threatens the quality of final fertilizer. The production principle of organic fertilizer comes from green plants and animals, which is the key to provide plant nutrition in soil layer by using carbon containing chemicals.

According to the processing route of organic fertilizer making machine, it removes harmful substances and contains a lot of favorable chemicals. Why do organic fertilizers become particles in the production and production of organic fertilizers? Organic fertilizer equipment manufacturers analyze the advantages of organic fertilizer and powder fertilizer.

1. It is very important to master the particle size distribution of fertilizer for the storage and transportation of fertilizer. The physical state of organic fertilizer particles is good, but the powder is difficult to assemble, so it has good transport characteristics.

2. Low water soluble fertilizers generally grind small particles to ensure that they melt reasonably and rapidly in the soil layer and are digested and absorbed by green plants.

3. Fertilizer granulation improves the production process of agriculture and animal husbandry. The fertilizer granules processed by double roller granulator have the function of slow-release fertilizer, which is convenient and not easy to be blown away by wind.

4. The organic fertilizer production line can add some inorganic components to improve the fertility of organic fertilizer, and powder fertilizer and inorganic components can easily digest and absorb water and bulk materials.