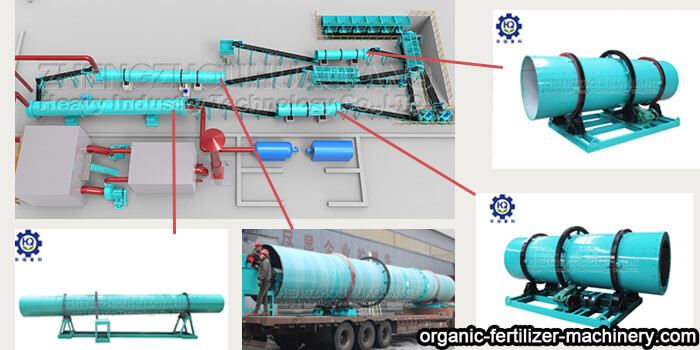

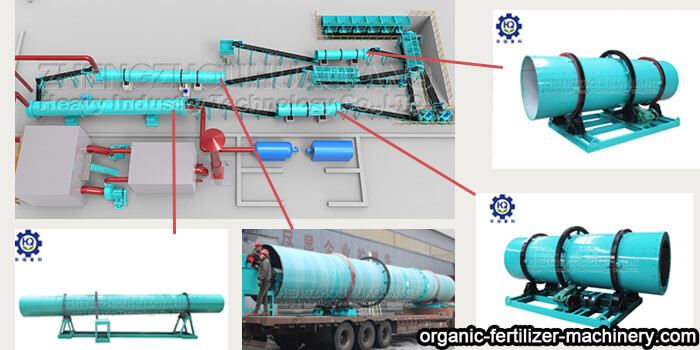

NPK fertilizer production line includes several large-scale rotary drum equipment, which is large in volume and high in cost, and plays an important role in fertilizer production. The rotary drum equipment of NPK fertilizer production line includes drum dryer, cooler, rotary drum granulator and coating machine. The structure of these large fertilizer equipment is roughly the same, mainly composed of drum device, supporting wheel device, gear device, transmission device and sealing device.

Due to the similar construction of the drum equipment, the installation procedure of these equipments should be noted when installing the NPK fertilizer production line. According to the characteristics of this kind of equipment, correct installation ensures the normal operation of these large-scale equipment.

The land construction of the NPK fertilizer production line is the key to equipment installation. After the foundation construction, the following problems should be noted when accepting the foundation of the civil works:(1) The foundations of rotary drum equipment should be interrelated, and most of the entrances and exits of the equipment are directly connected with other equipment. If there is a big deviation in the positioning of the supporting wheel seat, the installation of other equipment will be deviated greatly. Therefore, it is necessary to verify the vertical and horizontal center line of the foundation and the center line of the bolt hole of the foot accurately. The allowable deviations are 20 mm and 10 mm, respectively.

(2) Drum dryer, cooler, rotary drum granulator, coating machine, these drum-type equipment installation have some degree of tilt. Therefore, in the installation, the level of the front and rear roller seats, pinion gears, reducer and motor should be measured relative to the elevation of the base, and the relative deviation of the elevation is 20mm.

(3) In order to make some adjustment allowance for drum dryer, cooler, drum granulator, coating machine and other equipment in the process of calibration, it is necessary to ensure the depth of bolt hole and the plumbness of hole wall. The allowable deviations are 20mm and 10mm respectively.