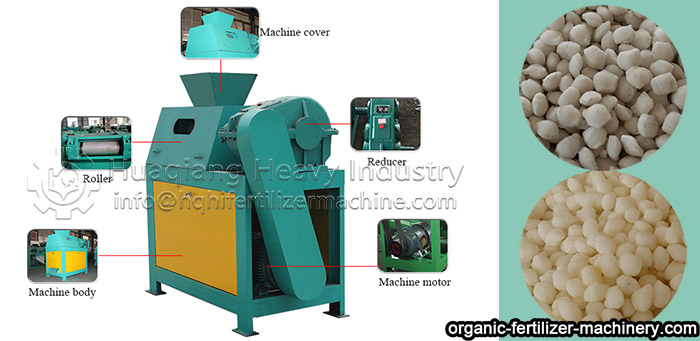

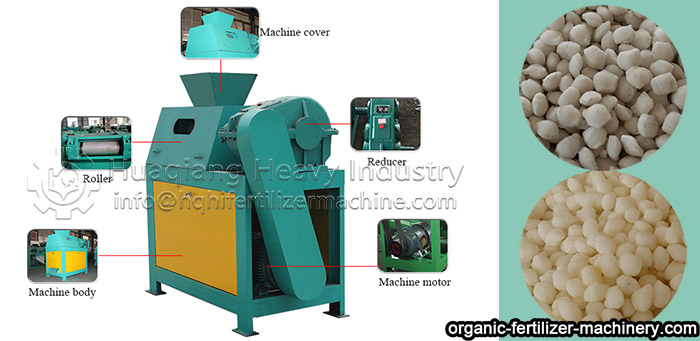

1. Installation:

After arriving at the plant, the roller extrusion organic fertilizer granulator will be installed with the granulator as the main machine according to the number of units and the organic fertilizer manufacturing process flow chart to find out the elevation and horizontal position. There are corner holes in the frame, which can be installed on the concrete (the solid vibration is not large, and a very solid concrete foundation is not required).

2. Debugging:

(1) Adjustment of press roll clearance

In the production process, it is sometimes necessary to increase the data output or data biting angle. In this case, the distance between the two compression shafts can be increased and the clearance between the drive shaft roller and the driven shaft can be increased.

The steps are as follows: stop the roller granulator, remove the frame above the two bearing blocks, adjust the adjusting plate between the two bearing blocks to the required thickness, prevent the roller collision between the two rollers, and maintain the minimum clearance of 0.3-1 mm.

(2) Ball and socket alignment adjustment

The ball and socket are formed by the pits on the surface of the main roller, so there are problems of axial alignment and circumferential alignment.

Axial alignment has been adjusted during installation. Generally speaking, there is little possibility of adjustment. When adjustment is needed, tighten or loosen the gland on both sides of the passive bearing seat, so as to push the displacement of the eccentric sleeve corresponding to the driving shaft roller.

Align the circumference. The steps for circumferential alignment are as follows: Loosen the 6 connecting bolts of the driven gear and the adjusting sleeve, so that the adjusting sleeve and the driven gear are slightly separated. Since one ball and socket adjustment is considered in the design, and two adjustment bolts are provided, the deviation can be adjusted no matter how large the deviation is. Because the ball socket of the double roller granulator is too small, the cardboard is placed between the two rollers during adjustment. After rolling, you can see whether the adjustment has achieved the purpose. After alignment, tighten 8 connecting bolts.

We provide NPK fertilizer granulator equipment, users can get professional engineer guidance after purchasing the equipment, we provide help in installation.