China Fertilizer Machine Manufacturers - Tianci has long been committed to the development of complete NPK compound fertilizer granulation production equipment, specializing in fertilizer production technology, new technology, new equipment research and technical services. We provide customers with overall design and technical guidance for the NPK fertilizer production process with annual output of 1-30,000 tons. We also supply complete sets of equipment and provide one-stop commissioning and production services.

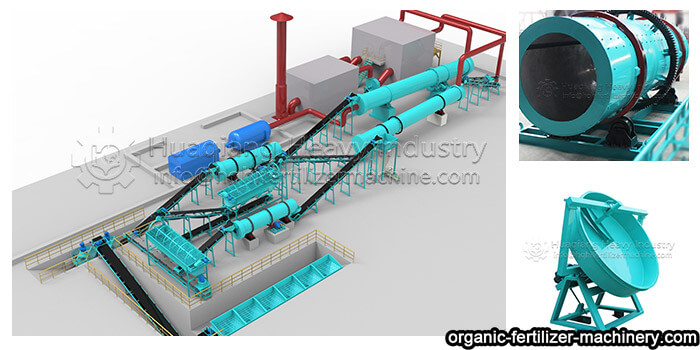

Our NPK fertilizer production equipment main products: rotary drum granulator, double roller press granulator, disc granulator, drum dryer, mixer, screening machine, conveyor and other complete production equipment.

1. The adjustment range of product nitrogen content is wide. The nitrogen content can reach more than 30%. It can produce not only ternary compound fertilizer (such as 30:5:5), but also unit fertilizer (such as granular nitrogen fertilizer 25:0:0) and binary compound fertilizer (such as 30:0:5).

2. Compound fertilizer products do not agglomerate. The water content of the product is less than 1.5%, the packaging temperature of the product is less than 40 C, the product has high particle strength, smooth and round appearance, and the product can reach half a year without caking after simple anti-caking coating treatment.

3. Compound fertilizer production system is flexible and adaptable to raw materials.

4. The NPK compound fertilizer production process can produce multi-variety/multi-type compound fertilizer products, which can produce urea-based type, and can also produce chlorine-based type, and can also produce sulfur-based and nitro-type.

5. Fertilizer production equipment is not blocked and can realize long-term continuous and stable operation.

6. Our equipment expands the variety of raw materials. Low-cost raw materials such as wet ammonium chloride, wet potassium chloride, calcium, magnesium phosphate and calcium hydrogen phosphate can be used in large quantities.

7. NPK fertilizer production process is simple, maintenance operation and production management are convenient, production environment is good, can achieve standard discharge and clean production.

8. Investment and operation are the most economical. Compared with the same type, equipment investment is less, energy consumption is lower and production cost is lower.