Roller press granulator machine is used for powder granulation, which has great development in NPK fertilizer granulation. Ammonium sulfate, ammonium chloride, ammonium phosphate, ammonium carbonate, ammonium chloride, ammonium sulfate, calcium, magnesium, phosphorus, urea and other chemiacl materials can be used as raw materials for the production of roller press granulator. Roller press granulator is usually equipped in NPK fertilizer production line. It can finish the pelletizing of NPK fertilizer well.

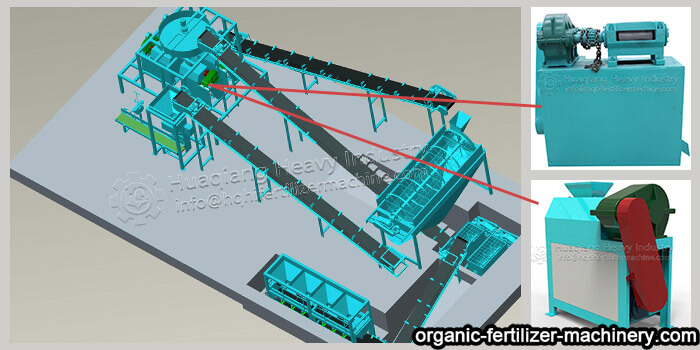

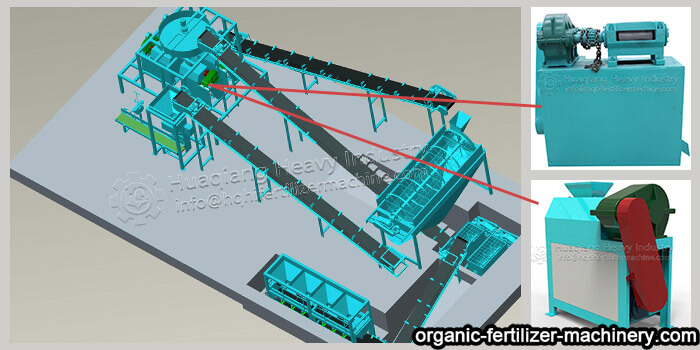

Roller press granulator is suitable for NPK fertilizer granulation. The main reason is that its granulation method and process determine that it can adapt to the characteristics of NPK raw materials. Therefore, the product effect of roller press granulator fertilizer production line is good and the production efficiency is high. From the structural point of view, the roller press granulator machine is mainly composed of four parts.

(1) Conveyor of roller press granulator. In order to ensure the feeding continuity of the extrusion granulation system of the granulator, the equipment is equipped with a conveying device. The appropriate feeding speed can ensure a certain level of material in the feeding hopper.

(2) Forced screw feeding device. The forced feeding device is easy to control the feeding speed of NPK fertilizer, increase the biting angle and increase the output. Moreover, in the forced feeding device, part of the material can be pre-degassed and compacted, thus improving product quality.

(3) Extrusion roll of roller press granulator. A pair of rolls rotating in opposite direction adopt double axle output reducer and drum gear coupling, which can effectively protect rolls and main bearings from damage and improve transmission efficiency.

(4) Granulator. The crushing chamber is composed of a crushing box body, a crushing spindle, a cross rotating blade and a comb plate. The motor drives the spindle to rotate at high speed to crush the sheet material.