Slow-release controlled fertilizer can release nutrients slowly in the soil, which meets the nutrient requirements of the whole crop growth period. In the process of NPK fertilizer production, the purpose of slow release and control of fertilizer is achieved by granulation and coating.

Slow-release fertilizer refers to the release rate of available nutrients from plants after fertilizer is applied to soil is lower than that of instant fertilizer. Controlled-release fertilizer refers to the regulation of nutrient release according to the set release mode and the law of nutrient uptake by crops. The release not only refers to the release period of fertilizer, but also refers to the release rate of nutrients in fertilizer consistent with the law of crop fertilizer demand.

Features of controlled-release fertilizers

Ideally, controlled release fertilizers can artificially control the supply and release rate of nutrients according to the demand for nutrients at different stages of crop growth. That is, nutrients can be released for use when the crop needs them, and retained in the soil when they are not needed, so that a single application can satisfy all stages of crop growth. Section needs.

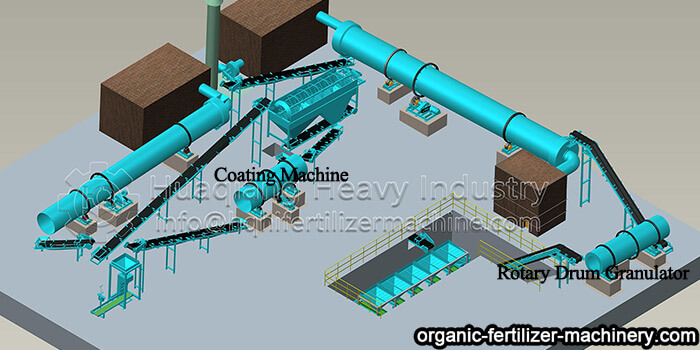

NPK fertilizer production line can process slow-release and controlled fertilizer by fluidization. The main production processes are: batching, mixing, granulation, drying, cooling, screening, coating and packing. Fertilizer granulator machine is the key to slow-release and controlled fertilizer processing, which determines the size, shape and hardness of fertilizer particles. Fertilizer granulator machine determines the appearance of the product, and the physical shape of the product also affects the fertilizer effect.

Rotary drum granulator is commonly used in slow-release and controlled fertilizer production for granulation. The drum granulator has large production capacity, low production cost and spherical granules, which is in line with the production requirements of slow release fertilizer. The final stage of NPK fertilizer production and processing is to be coated, and after the particles are coated, it becomes a slow release fertilizer.