Different types of compound fertilizer equipment have different water content, but NPK fertilizer production process is basically the same, there are common points. In the production of compound fertilizer, the moisture content should not exceed 35%. Here's how to limit the moisture content in the use of compound fertilizer equipment.

First, when NPK fertilizer is produced, its moisture content is too high to form, just like sludge. If the particles with moisture content more than 35% are sealed and packed, the fertilizer will eventually become a mass.

Secondly, according to the standard of fertilizer products, the water content can not exceed 35%.

Thirdly, the moisture content of raw materials is too large to be crushed, it is not suitable for molding and packaging.

Zhengzhou Huaqiang Heavy Industry Technology Co.,Ltd. specializes in the production of new compound fertilizer equipment, providing the price of compound fertilizer machines and detailed machine parameters. Our NPK fertilizer production process is suitable for the fertilizer market, and suitable for large, medium and small enterprises in various regions of the world.

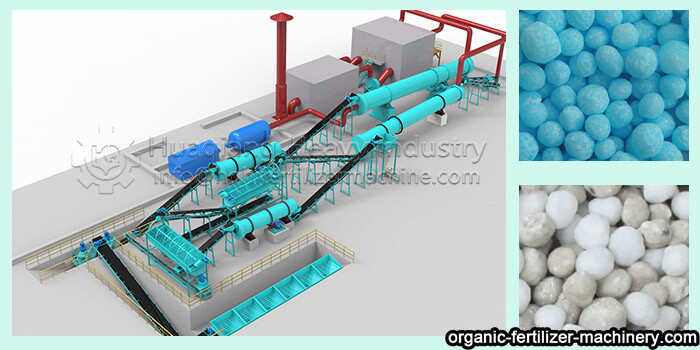

Characteristics of Compound Fertilizer Equipment:

1. Applicability and wide range of raw materials: suitable for direct consumption of crude fiber organic waste of 30% or so of water containing livestock and poultry manure, sugar mill sludge, municipal sludge, paper sludge, distiller's grains, straw, and grass charcoal after fermentation, and can produce compound fertilizer with spherical particles.

2. Fertilizer granulator machine has high pelletizing rate and survival rate of biological bacteria: fertilizer process can make the sphericity rate reach 90-95% or more, and the low temperature and high air volume drying new technology can make the survival rate of the microbial bacteria reach over 90%.

3. Short process flow and low operating cost. We provide a variety of fertilizer production processes, such as sludge disc granulation process, organic-inorganic fertilizer drum granulation process, compound fertilizer steam drum granulation process.