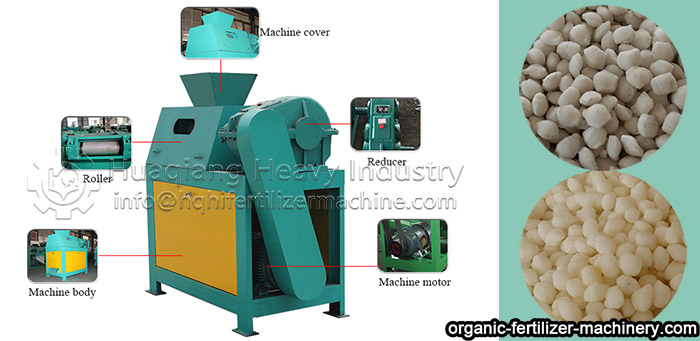

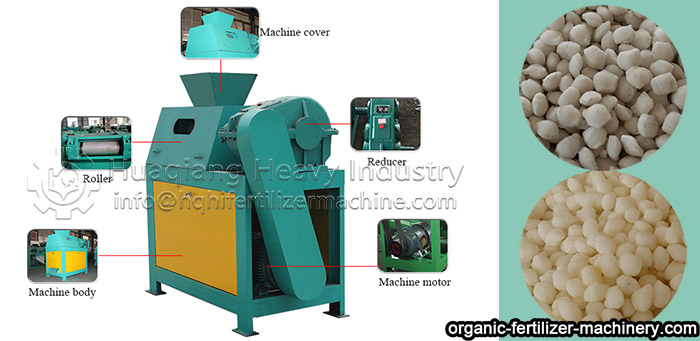

Double roller granulator is widely used in the granulation of bio organic fertilizer. The roller press granulator is inevitably worn in the process of fertilizer granulation and extrusion. Roller press pelletizer is mainly for dry powder materials. Due to the different hardness of materials, uneven force will be produced in the process of extrusion and rounding, which will increase the wear of roller skin. We need to start from a number of wear causes and consider the corresponding measures. How to solve this kind of problem?

In terms of different material factors, because the surface of double roller pelletizer is friction material and direct force, when the roller surface is worn, the friction and back pressure of material can not be ignored. This force requires higher quality roll skin, lower mass wear rate and lower mass wear rate. If the feed of the fertilizer production line is not uniform, the center of the parallel rod shaft of the double roller granulator is parallel to the roll surface. The feed at one end and the feed at the other end will cause the uneven force at both ends of the roll, thus increasing the friction between the roll and the material, resulting in roll wear.

Because the roller cover of bio organic fertilizer pelletizer is made of stainless steel, it has a strong reaction to the pH of the material. Due to the lack of moisture and alkalinity, the surface of the roller will be corroded by acid and alkali, and the roller will be damaged. If the operation procedure cannot be operated, the gap between the rolls will not be adjusted correctly and will contain impurities such as iron and sulfur. The color phase will seriously damage the roll surface. Measures to reduce the wear of roller shell of biological fertilizer granulation pelletizer.

In the process of organic fertilizer making machine, roller wear is inevitable. If used properly, it can effectively reduce the wear of the roller skin and extend the service life of the roller.

According to the above factors, wear can be reduced from the following aspects. The new type of bio-organic fertilizer extrusion granulator can improve the dryness of the granules, without forming adhesion after granulation, and improve the quality of granulated products.