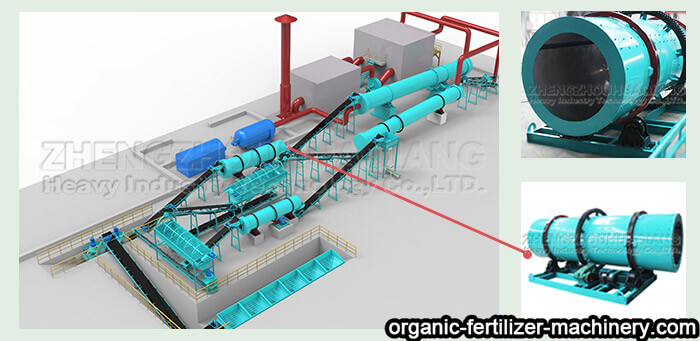

Rotary drum granulator is the main granulation equipment of NPK fertilizer production line, which uses powder ingredient and agglomeration granulation method to make NPK compound fertilizer into shape. The drum granulator developed by our factory adopts a new generation of granulation technology, which improves the forming rate of compound fertilizer particles and the qualified proportion of primary granulation.

Rotary drum granulator can make NPK compound fertilizer into granular form which is easy to store and release slowly, thus greatly prolonging the fertilizer efficiency of organic fertilizer. Rotary drum granulator is suitable for cold and hot granulation. It uses wet granulation of aggregates, and adds a certain amount of water or steam to the cylinder, so that the extrusion force between the particles of the material can be agglomerated into a ball.

In order to improve the granulation performance of drum granulator, we improved the drying process of NPK fertilizer production line after granulation. It can shorten the drying time of fertilizer production, minimize the damage of compound fertilizer particles in the drying process, and increase the number and strength of qualified particles in the drum dryer.

For NPK fertilizer granulation, the granularity quality of granulation depend to a certain extent on the granularity of proportioning and feed back. The quality of batching is usually required for compound granulation, and the quality of returned materials is the key to control the production of rotary drum granulator. On the basis of guaranteeing nutrient composition, the quality of returned material mainly depends on the size and distribution of returned material. In order to ensure the quality of returned materials, we have set up chain crusher in NPK fertilizer production line.

Chain crusher re-crushes the unqualified returned material, and the crushed powder meets the granulation requirements of the rotary drum granulator.