The industrialized production of organic fertilizer reduces the area occupied by raw material treatment, shortens the fermentation time, and facilitates transportation and storage. By collecting waste materials, dehydration, fermentation, granulation and other industrial treatment processes, the physical and chemical properties, commercial properties and economic properties of organic fertilizer produced are good. The treatment of modern organic fertilizer production line has greatly improved the utilization rate of organic waste. Large-scale organic fertilizer production line will centralize raw materials, with high mechanization, less labor, low cost and scale benefit. Only a few workers can operate the organic fertilizer equipment by simple mechanical operation, and the organic fertilizer production cost is low.

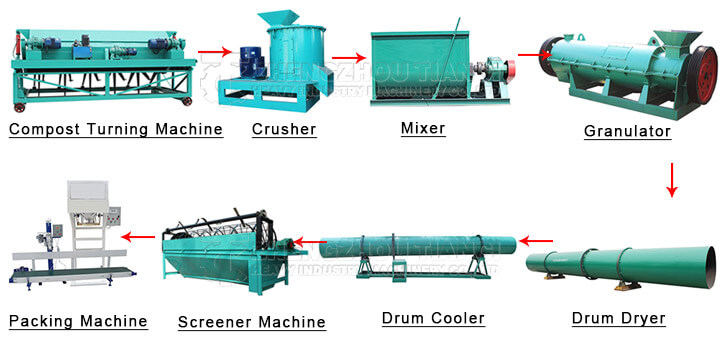

Turn the raw materials to compost. And shorter and compost time.

Mixing machine(Two mixer machine can make the whole production line work continuously) (1-2workers)

The mixed material should be mixed completely ,then get into granulator . Also can add some water when you mixing

Granulation, drying, cooling (1worker)

Processing powder to granules, the moisture of fertilizer is a bit high, then drying and cooling the granules.

Screening and return crushing

The screener machine screening the qualified granules, the small diameter particle may be screened down for twice processing. And bigger granules go to the crusher machine again.

Packaging (1-2workers, storage need 1-2workers)

Filling the bags, and sealing. After package ,the fertilizer can be sold.