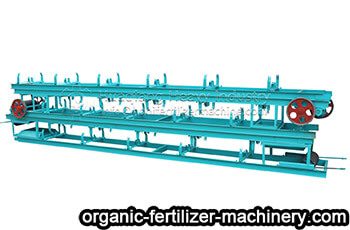

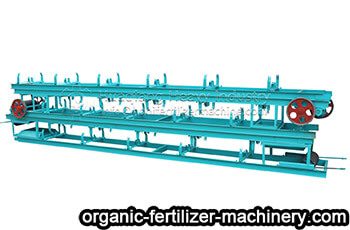

Belt conveyor machine is mainly composed of frame, conveyor belt, idler, drum, tensioning device, transmission device and other components. It is widely used in coal mine, cement, grain and other industries. When compound fertilizer plant produces fertilizer, the material is conveyed by belt conveyor. Belt conveyor can form a material conveying process from the feeding point to the final unloading point. It can not only transport bulk materials, but also carry out the transport of finished goods. It can also meet the technological requirements of various production processes. In organic fertilizer production line, belt conveyor can form a material transportation process from the feeding point to the final unloading point. As a manufacturer of organic fertilizer machinery, besides belt conveyors, we also provide a variety of related fertilizer plant equipment, such as granulator, crusher.

Specification for the use of belt conveyor machine in organic fertilizer production

When the belt conveyor is working on the fertilizer production line, pay attention to these operating specifications to avoid machine failures and accidents.

Specification for the use of belt conveyor machine in organic fertilizer production

When the belt conveyor is working on the fertilizer production line, pay attention to these operating specifications to avoid machine failures and accidents.1. Belt conveyor machine has fixed type and mobile type. Fixed conveyor should be installed in a fixed position. Before the mobile conveyor is running, the wheels should be braked to avoid moving in the work. When multiple conveyors are working, there should be appropriate space between the conveyors.

2. Before the start-up of the conveyor machine, the belt tightness should be adjusted, the transmission components such as bearings, gears, chains should be good, the supporting rollers and protective devices should be complete, the electrical protection should be well connected to zero or grounding, and the width of the conveyor belt should be consistent with that of the drum.

3. When the belt conveyor machine starts up, it should run without load first, and then it can be fed after normal operation. It is forbidden to start after fed. When several conveyors are running in series, they should start in sequence from the unloading end, and only after all the conveyors are in normal operation can they be loaded. When feeding, the material should be uniformly loaded at the central position of the conveyor belt, and the height should be reduced as far as possible to reduce the impact of falling material on the conveyor belt and idlers.

4. In the operation of conveyor, belt deviation should be stopped and adjusted to avoid wear edge and increase load. Pedestrians are forbidden when the conveyor is running, and cleaning or overhaul operations are forbidden when the conveyor is running. When the conveyor belt slips, it is forbidden to pull by hand. When conveying large material by belt conveyor, protective devices such as material plate or fence should be installed on both sides of conveyor belt.

5. Adjusting the unloading height of the belt conveyor should be carried out during parking. After adjustment, the connecting nut should be tightened and the insurance pin inserted. Conveyor motor must be well insulated, mobile conveyor cable should not be pulled or dragged, the motor should be grounded.

6. When the conveyor needs to stop in transportation, it must stop feeding and stop until the material on the belt is discharged. After the operation is completed, the power supply should be disconnected, the material on the conveyor should be cleared, and the motor should be covered with a protective cover.