Fertilizer production equipment is an important tool for the development of agriculture. Fertilizer manufacturing process technology can not only help to improve the living environment, but also create profits. The fertilizer manufacturing process technology should be combined with various granulating experience and the use requirements of different materials to produce organic fertilizer, compound fertilizer and compound fertilizer according to the demand of different kinds of fertilizer granulating.

The granulation methods of fertilizer manufacturing process technology include fertilizer granulation production line and urea based spray granulation equipment.

Spray granulation: the main raw material of this process is the concentrated liquid of organic waste water produced in the fermentation industry. The organic waste liquid is concentrated by multi effect evaporation, and then mixed with a certain amount of mineral fertilizer to form slurry, which is sent to the spray granulation machine and dried into granules by high temperature hot air.

The application of spray granulation is not as convenient as the granulation production line, which has the following characteristics:

1. The scope of organic fertilizer production is narrow, and the selection of materials is limited to slurry.

2. Large equipment investment and high energy consumption.

3. It integrates spraying, drying and granulation, and is easy to operate.

4. The product is ball shaped, with good physical properties and high commodity grade.

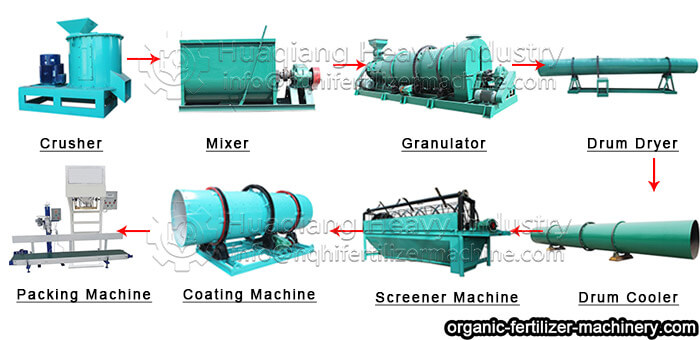

Common flow of fertilizer manufacturing process technology

1) Fermentation turner

2) Forklift. Use forklift to transfer the fermented organic fertilizer to the semi-finished product stacking area, so as to deal with the fermented organic fertilizer thrown by the turner every day.

3) Drum screening machine. The fermented organic fertilizer will be screened, and the large blocks and sundries will be separated out for the next step of crushing and packaging.

4) Crusher. The large debris and stones in the screened organic fertilizer are separated and crushed, which is beautiful and can ensure the quality of the product.

5) Mixer

7) Dryer, cooler. Dry and cool the particles.

Powdery fertilizer is not easy to use in agriculture, it is easy to produce dust, causing pollution and loss. The fertilizer manufacturing process technology makes the material granulated and greatly improves the quality of the product.