The organic fertilizer processed by the pig manure organic fertilizer production line has the functions of improving soil aggregate structure and improving soil fertility, and is beneficial to improving crop yield and quality. Organic fertilizer production line suitable for green food production. The pig manure organic fertilizer equipment treats environmentally-friendly waste into high-quality organic fertilizer, which has low production cost and high product value.

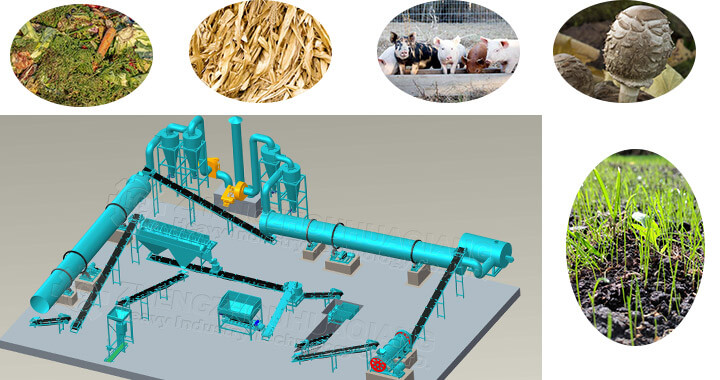

Pig manure treatment, accumulation of bacteria after accumulation of bacteria, turning materials of turner, fermentation and decomposition, machine processing of organic fertilizer (crushing, mixing, granulation, drying, cooling, screening, packaging), bio-organic fertilizer.

Fertilizer conditions for pig manure organic fertilizer

The moisture content of pig manure compost is between 60% and 70%.

Add harmless bacteria.

Add corn stalk, peanut shell, mushroom residue, dregs and other accessories.

The mixture is stacked and sent to the fermentation tank.

After the compost is heated, the material is turned over in time, and the fermentation temperature can reach 60-70℃.

The composting mixture has a carbon to nitrogen ratio of <25.

The fermentation time is about 10 to 20 days.

Compost turning machine: The compost turner machine throws the material. When the temperature rises above 55℃, turning over the compost once a day can promote the evaporation of water in the compost, make oxygen enter the fermentation reactor, and accelerate the fermentation.

Crusher: Crushing compost and bulk materials to obtain powdered organic fertilizer after crushing.

Mixer: Different materials are thoroughly mixed in the mixer.

Granulator: The fermented pig manure, straw, mushroom residue and other organic fertilizers are made into granules.

Drum dryer: Removes the moisture of the pig manure organic fertilizer granules, making the organic fertilizer easy to store.

Drum cooler: Cool the dried particles to avoid the heat absorption of organic fertilizer.

Packing machine: Automatically quantitatively pack the pig manure organic fertilizer, and then put it into stock.