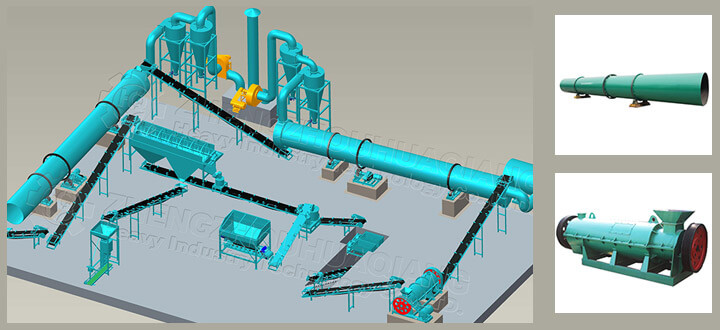

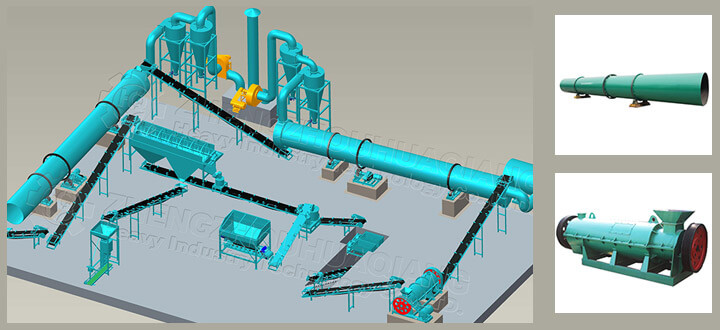

A chicken manure, duck manure, pig manure, cow dung bio-organic fertilizer production line, livestock and poultry manure can be used as raw materials for organic fertilizer equipment. The bio-organic fertilizer production line is based on organic matter such as livestock manure, straw, soybean meal, sesame cake and dregs, and uses bio-compost fermentation technology to produce organic fertilizer. The organic fertilizer machine of the organic fertilizer production line reuses organic waste, which has high product value and low production cost.

So what equipment is needed to build a bio-organic fertilizer production line?

Compost turning machine

If compost depends on natural fermentation, not only the fermentation speed is slow but also the fermentation quality is not good. The compost turning machine makes the material contact with the air and provides sufficient oxygen for continuous aerobic fermentation. The fermentation process of the compost turner realizes automatic and intelligent control.

Fertilizer crushing machine

The semi-wet material crusher is used for pulverizing the fermented material, and has a strong adaptability to the moisture content of the material, and the moisture of the organic fertilizer material crushed by the semi-wet material crusher can reach 25-50%.

The chain crusher is used for crushing before granulation and recycling in organic fertilizer production line, which affects the quality of organic fertilizer granulation.

Disc mixer

The disc mixer makes the material fully stirred evenly, improves the uniformity of material mixing, and is suitable for mixing with raw materials.

Organic fertilizer granulator

The granulator is the important equipment of the organic fertilizer production line. The new type organic fertilizer granulator is widely used in the production of organic fertilizer and bio-organic fertilizer granules. The new type organic fertilizer granulator has a uniform fertilizer particle size, a smooth surface, a high particle strength, a high pelletizing rate of the fertilizer, and a low return rate.

Rotary fertilizer dryer

The rotary dryer is in the shape of a slightly inclined drum, and the material is lifted up by the copying plate in the air to be in contact with the hot air, and is quickly dried. The fertilizer dryer can be used for the production of compound fertilizer, and can also be used for drying other materials, and the output is large, and the organic fertilizer device has the advantages of high efficiency.

Rotary fertilizer cooler

The rotary cooler is similar in appearance to the dryer. The dried hot particles are cooled in the organic fertilizer production line, and the cooled organic fertilizer is easy to store.

Drum screening machine

The drum screening machine is used to screen organic fertilizer granules and powder materials to evenly classify the finished products. In the bio-organic fertilizer production line, a first-stage screening machine and a second-stage screening machine can be set, and the multiple-screening organic fertilizer particles have higher yield and better particles.

Organic fertilizer packing machine

The granule packing machine can automatically package organic fertilizer for the end of the bio-organic fertilizer production line to realize the automatic production of the fertilizer production line. The packaging machine includes components such as a quantitative packing scale, a silo, and an automatic sewing machine.

In the bio-organic fertilizer production line, it is also possible to add intermediate and trace elements necessary for 16 crops such as calcium, magnesium, iron, zinc and boron. The fertilizer produced by the organic fertilizer machine is comprehensive in nutrition, meets the needs of crop diversification, and is an essential fertilizer for producing green food.

Related: Organic fertilizer granulating production line